What Innovations Are Driving the Demand for Brazed Plate Heat Exchangers?

In recent years, the industrial landscape has visible a full-size shift toward extra efficient and sustainable answers. Among these innovations, brazed plate heat exchangers have received incredible attention for their effectiveness in heat switch packages. As industries try to improve efficiency and reduce electricity intake, the call for for these warmth exchangers has surged. This blog explores the key improvements that are riding this developing demand, emphasizing the benefits and improvements that make brazed plate heat exchangers a desired preference in various sectors.

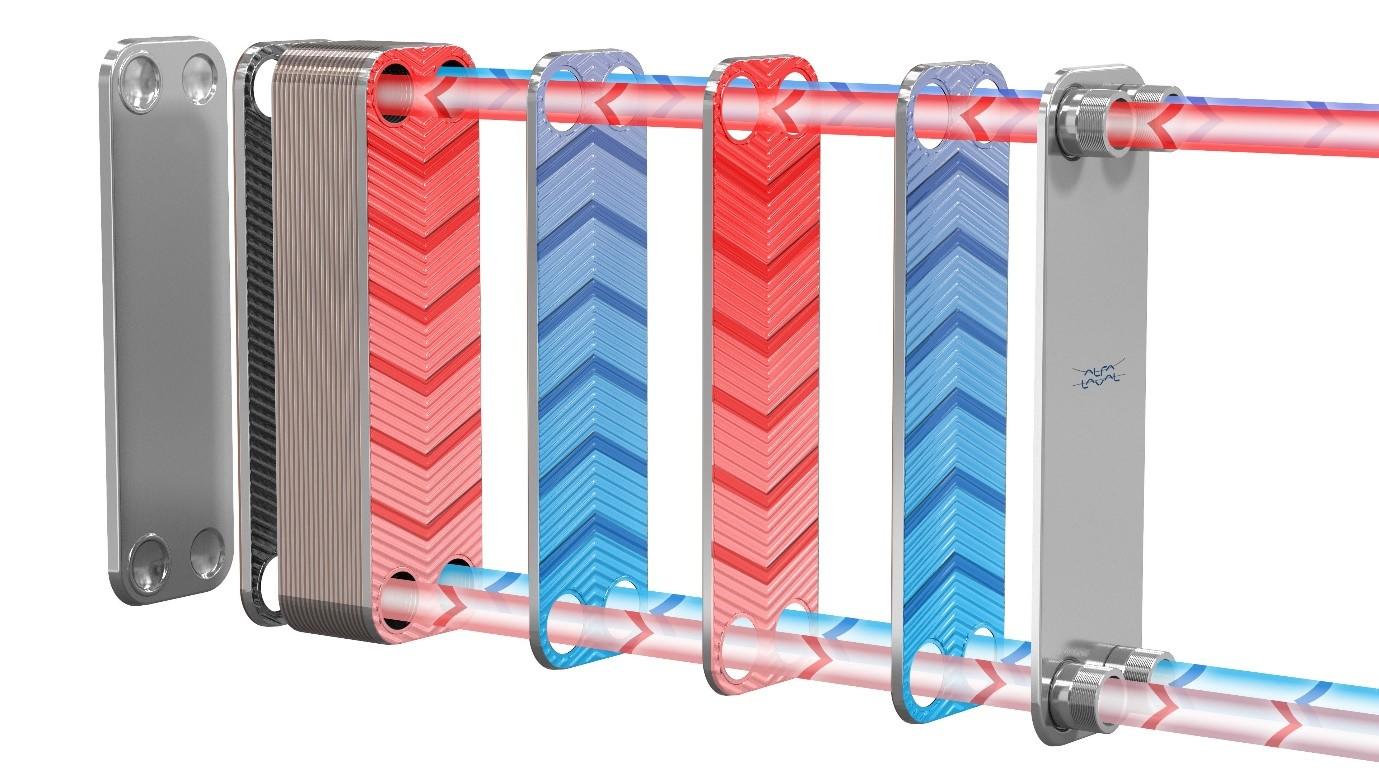

Understanding Brazed Plate Heat Exchangers

Before delving into the innovations, it’s far important to recognize what brazed plate heat exchangers are. These heat exchangers encompass a couple of thin plates stacked collectively, with channels shaped between them to permit the drift of two fluids at exceptional temperatures. The plates are brazed together, generally with copper or nickel, to create a compact and robust shape. This design allows green warmness switch among fluids, making them best for packages in HVAC, refrigeration, and commercial strategies.

1. Compact Design and Space Efficiency

One of the most full-size improvements using the demand for brazed plate warmth exchangers is their compact design. Traditional heat exchangers often take in a large amount of space, making them much less suitable for programs in which space is a top rate. In assessment, brazed plate heat exchangers are much smaller and lighter while offering the same or even greater warmness switch efficiency.

Benefits of Compact Design

-

Reduced Footprint: The smaller length permits for installation in tight areas, that is particularly useful in retrofitting present systems.

-

Lower Installation Costs: Less space required interprets to reduced set up hard work and material costs.

-

Increased Flexibility: Their compact nature lets in for extra flexibility in gadget layout and integration into various applications.

2. Enhanced Thermal Efficiency

Thermal performance is a crucial issue inside the performance of heat exchangers. Brazed plate warmth exchangers excel on this region because of their particular design and construction.

Innovations in Thermal Efficiency

-

Optimized Plate Geometry: Advances in plate design have brought about stepped forward turbulence, which complements heat transfer between fluids. This way that brazed plate warmness exchangers can gain higher heat switch coefficients than traditional models.

-

Improved Flow Patterns: The configuration of the plates lets in for counterflow and crossflow arrangements, maximizing the thermal alternate between the fluids.

3. Superior Durability and Reliability

The materials used within the construction of brazed plate warmness exchangers appreciably contribute to their durability. Most typically crafted from chrome steel or different corrosion-resistant substances, those warmness exchangers are designed to withstand harsh running conditions.

Durability Innovations

-

Corrosion Resistance: The use of stainless steel heat exchanger inside the brazing manner provides exquisite resistance to corrosion, making them appropriate for a huge range of packages, such as those concerning competitive chemical compounds.

-

High-Pressure Capabilities: Many current brazed plate warmness exchangers are engineered to handle excessive stress, letting them carry out correctly in annoying environments.

4. Improved Manufacturing Techniques

Manufacturing approaches have also visible substantial improvements, contributing to the rising call for for brazed plate warmness exchangers. Innovations in manufacturing strategies have enabled manufacturers to produce these warmness exchangers more efficiently and value-effectively.

Key Manufacturing Innovations

-

Automated Production Lines: Automation has streamlined the producing system, lowering lead instances and increasing production capability. This efficiency permits manufacturers to satisfy the growing demand without sacrificing first-class.

-

Quality Control Measures: Enhanced quality manage measures make sure that every brazed plate warmness exchanger meets stringent overall performance requirements, further growing reliability and purchaser delight.

5. Versatility Across Industries

The versatility of brazed plate warmness exchangers is any other thing riding their call for. They are suitable for a wide variety of applications, from residential HVAC structures to massive-scale commercial processes.

Industries Benefiting from Brazed Plate Heat Exchangers

-

HVAC and Refrigeration: These warmth exchangers are extensively utilized in heating, ventilation, air con, and refrigeration systems due to their compact size and high performance.

-

Chemical Processing: The resistance to corrosion and potential to handle high pressures make brazed plate warmth exchangers best for chemical processing programs.

-

Food and Beverage Industry: The hygienic layout and smooth cleaning talents of stainless-steel heat exchangers make them suitable for use in food and beverage processing.

6. Sustainability and Energy Efficiency

As international industries face increasing stress to adopt sustainable practices, the demand for energy-green answers has surged. Brazed plate warmth exchangers make contributions to strength financial savings and decreased environmental effect.

Innovations Supporting Sustainability

-

Energy Recovery Systems: Many current brazed plate warmth exchangers are designed for electricity recuperation applications, taking pictures waste warmness and reusing it in different tactics.

-

Lower Carbon Footprint: By enhancing strength efficiency, these warmth exchangers help reduce the general carbon footprint of industrial operations.

7. Technological Advancements in Control Systems

The integration of superior control systems with brazed plate warmness exchangers has similarly better their overall performance and reliability. Smart technology allows for better tracking and control of warmth alternate procedures.

Benefits of Advanced Control Systems

-

Real-Time Monitoring: Advanced sensors offer actual-time facts on temperature, pressure, and drift prices, bearing in mind quick adjustments to optimize performance.

-

Predictive Maintenance: The use of IoT (Internet of Things) generation permits predictive upkeep, decreasing downtime and improving general efficiency.

Conclusion

The call for for brazed plate warmness exchangers keeps to upward rise as industries searching for innovative answers that promote performance, sustainability, and versatility. The innovations discussed, along with compact design, better thermal efficiency, advanced durability, improved production techniques, and technological advancements, function brazed plate heat exchangers as a leading preference in heat switch applications.

As corporations increasingly recognize the blessings of these warmth exchangers, their integration into various commercial sectors will possibly develop. By investing in brazed plate warmness exchangers, companies not handiest improve their operational efficiency however additionally make contributions to a more sustainable future.