The Versatility of FIBC Bulk Bags: A Comprehensive Guide

Introduction:

FIBC bulk bags, also known as Flexible Intermediate Bulk Containers or simply big bags, are widely used in various industries for transporting and storing bulk materials. Their versatility, durability, and cost-effectiveness make them indispensable for businesses dealing with commodities such as grains, chemicals, minerals, and more. In this blog post, we delve into the world of FIBC bulk bags, exploring their uses, manufacturing process, pricing factors, and frequently asked questions.

Understanding FIBC Bags:

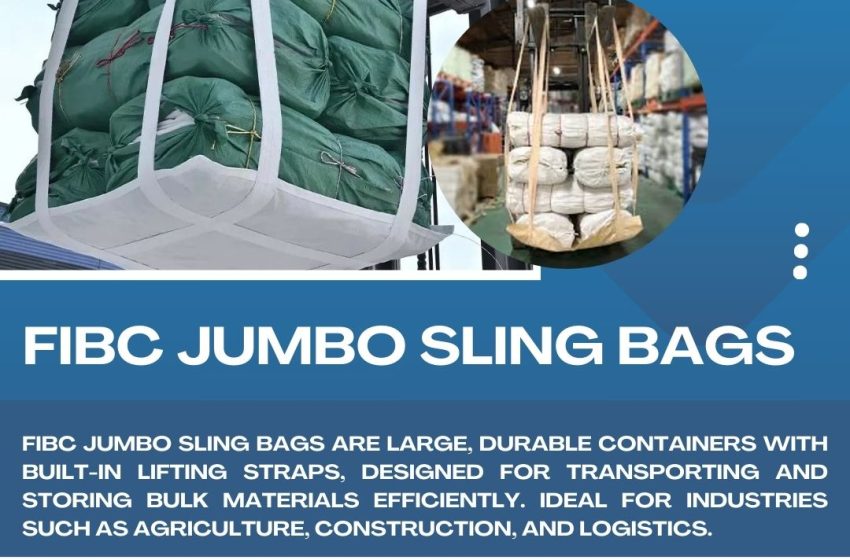

FIBC bags are large, flexible containers made from woven polypropylene fabric. They come in various sizes, shapes, and designs to suit different applications. These bags typically feature lifting loops or straps for easy handling using forklifts or cranes. FIBC bags offer significant advantages over traditional packaging methods, including:

-

Cost-effectiveness: FIBC bags reduce packaging costs by minimizing the need for pallets and reducing labor requirements for loading and unloading.

-

Space efficiency: Their ability to be stacked and stored in compact spaces optimizes warehouse storage.

-

Environmental friendliness: FIBC bags are reusable and recyclable, making them a sustainable packaging solution.

-

Versatility: FIBC bags can be customized with various features such as liners, discharge spouts, and sift-proof seams to accommodate different materials and handling requirements.

Manufacturing Process:

FIBC bags manufacturers in ahmedabad are manufactured through a series of steps that involve weaving, cutting, sewing, and assembly. The process typically includes the following stages:

-

Fabric production: Polypropylene resin is extruded into flat tape, which is then woven into fabric using specialized looms.

-

Cutting: The woven fabric is cut into panels of the required dimensions based on the bag design.

-

Sewing: The panels are stitched together using high-strength threads to form the body of the bag. Additional components such as lifting loops, discharge spouts, and liners are also attached during this stage.

-

Quality control: Each bag undergoes rigorous testing to ensure its strength, integrity, and compliance with industry standards.

Factors Affecting FIBC Bulk Bag Prices:

The cost of FIBC bulk bags can vary depending on several factors. Understanding these factors can help businesses make informed decisions when purchasing bulk bags. Some key factors influencing FIBC bag prices include:

-

Size and capacity: Larger bags with higher capacity generally cost more due to the increased material and manufacturing requirements.

-

Material type: The quality and type of fabric used in the construction of the bag impact its price. Specialty materials such as antistatic or UV-resistant fabric may incur additional costs.

-

Customization: Bags with customized features such as liners, discharge spouts, printing, and special stitching patterns may have higher prices compared to standard bags.

-

Quantity: Bulk purchases typically result in lower unit prices, as manufacturers offer discounts for larger orders.

Conclusion:

FIBC bulk bags price offer a versatile and cost-effective solution for transporting and storing bulk materials across various industries. Understanding their construction, pricing factors, and proper handling guidelines is essential for maximizing their benefits and ensuring optimal performance. With their durability, efficiency, and sustainability, FIBC bulk bags continue to be a preferred choice for businesses worldwide.

Frequently Asked Questions (FAQs):

1. What industries commonly use FIBC bulk bags?

FIBC bulk bags are used in a wide range of industries, including agriculture, construction, chemicals, food processing, pharmaceuticals, and mining. They are suitable for transporting and storing various materials such as grains, seeds, fertilizers, powders, and granular products.

2. Are FIBC bulk bags reusable?

Yes, FIBC bulk bags are designed for multiple uses, making them a cost-effective and sustainable packaging solution. Proper handling and storage can extend the lifespan of FIBC bags, allowing them to be reused numerous times.

3. How should FIBC bulk bags be stored to maintain their integrity?

FIBC bulk bags should be stored in a clean, dry, and well-ventilated area away from direct sunlight and sources of heat or moisture. Stacking bags on pallets and avoiding sharp objects or rough surfaces can help prevent damage and prolong their shelf life.

4. Can FIBC bulk bags be recycled?

Yes, FIBC bulk bags are recyclable, provided they are made from single-material construction without contaminants. Recycling facilities may accept clean and empty bags for processing into recycled materials that can be used in various applications such as new bag production or other plastic products.