Looking for a Simple Way to Improve Cooling? Try Air Cooled Heat Exchangers!

In industries in which cooling structures are important for operations, finding an efficient and cost-effective answer is key. Whether it’s a manufacturing unit, strength plant, or any business setup, the importance of preserving equipment and strategies cool can not be overstated. One of the satisfactory options for industries looking to improve their cooling structures is to consider air cooled warmth exchangers. These structures provide a easy, energy-green, and dependable manner to cool commercial system, which allows improve standard operational performance.

This article explores how air cooled heat exchangers paintings, their advantages, and why they might be the right choice to your business cooling needs. Additionally, we will touch on how they can complement other gadget like Nash liquid ring vacuum pumps to offer a properly-rounded cooling answer.

What Are Air Cooled Heat Exchangers?

Air cooled heat exchangers are a kind of warmness switch device designed to cool fluids the usage of ambient air. Instead of relying on water as a cooling medium, as in water-cooled structures, those heat exchangers use fans to draw air across the finned tubes sporting hot fluids. As the air moves over the tubes, it absorbs heat from the fluid, cooling it in the manner.

This simple layout makes air cooled warmth exchangers best for industries wherein water resources can be confined or in which water-cooled structures are impractical.

How Do Air Cooled Heat Exchangers Work?

The operating precept of air cooled warmth exchangers is straightforward. Hot fluid flows via a sequence of tubes at the same time as air is blown over the tubes by way of enthusiasts. The temperature difference among the new fluid and the cooler air causes the warmth to transfer from the fluid to the air. The warmness is then over excited by the airflow, cooling the fluid within the tubes.

Because air cooled heat exchangers depend solely on air, they’re especially useful in far flung places or industries in which water conservation is important. Additionally, they take away the want for water treatment, decreasing upkeep requirements and operational costs.

Key Benefits of Air Cooled Heat Exchangers

1. Energy Efficiency

One of the primary advantages of air cooled warmness exchangers is their energy performance. Since they do not depend upon a continuous supply of water, they keep power with the aid of removing the want for water pumps and cooling towers, which might be not unusual in water-cooled systems. By the use of ambient air for cooling, these structures require much less power to operate, specially whilst designed for low electricity consumption.

2. Cost-Effectiveness

While the preliminary investment in air cooled warmness exchangers may be slightly higher than water-cooled structures, the long-term financial savings on operational prices more than make up for it. With no need for water procurement, treatment, or disposal, those structures considerably reduce ongoing charges. Additionally, their low protection necessities result in fewer downtimes and repair charges.

3. Eco-Friendly Operation

In industries where environmental impact is a challenge, air cooled warmth exchangers provide a greener opportunity. Because they do now not eat large amounts of water or produce wastewater, they help preserve water resources and decrease the danger of infection. Furthermore, given that they’re energy-efficient, they make contributions to lowering the general carbon footprint of commercial operations.

4. Flexibility and Adaptability

Air cooled warmth exchangers are surprisingly adaptable and can be used across numerous industries, from strength era to chemical processing. Their modular design permits for easy installation in spaces in which water-cooled systems is possibly impractical. Additionally, their potential to carry out in excessive situations, which includes excessive ambient temperatures or dry climates, makes them an amazing desire for industries with specific cooling challenges.

5. Reliability and Durability

Built to withstand harsh commercial environments, air cooled warmth exchangers are regarded for his or her reliability and lengthy lifespan. Their simple design method fewer elements that are in all likelihood to fail, which interprets to more uptime to your commercial procedures. The reality that they do no longer depend on water also reduces the danger of corrosion, scale buildup, and other water-associated issues.

Applications of Air Cooled Heat Exchangers

Due to their performance and occasional environmental effect, air cooled heat exchangers are utilized in a huge variety of industries. Some of the most common programs consist of:

- Power Generation: Cooling turbines and generators to preserve ideal efficiency.

- Oil and Gas: Used in refineries and offshore systems where water is scarce or unavailable.

- Chemical Processing: Cooling method fluids and maintaining temperature control in reactors.

- HVAC Systems: Keeping air conditioning devices and refrigeration structures operating efficiently.

- Renewable Energy: Cooling structures in sun and wind power flowers.

How Do Air Cooled Heat Exchangers Complement Other Industrial Equipment?

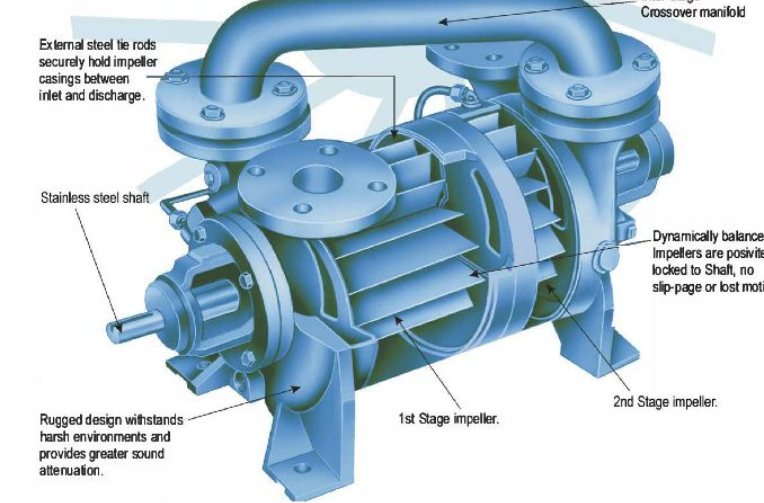

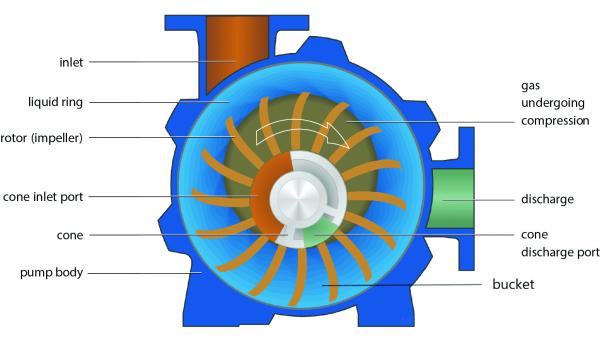

In industries that use complex machinery, air cooled warmness exchangers can paintings in tandem with different important equipment like Nash liquid ring vacuum pumps. These vacuum pumps, generally used in industries which includes chemical processing and power generation, require powerful cooling to maintain most desirable performance.

By pairing Nash liquid ring vacuum pumps with air cooled heat exchangers, industries can create a extra green cooling device that supports both vacuum operations and fluid temperature manage. This combination can assist decrease normal strength consumption, lessen preservation needs, and make certain that machinery operates smoothly.

How to Choose the Right Air Cooled Heat Exchanger for Your Needs

Selecting the right air cooled warmness exchanger on your industrial operation relies upon on numerous factors:

- Cooling Requirements: Understand the warmth load that desires to be dissipated and pick a device with the ability to handle your specific desires.

- Ambient Conditions: Consider the environmental situations in which the system will function. For example, in warm climates, you can want a greater powerful system to overcome higher ambient air temperatures.

- Space Availability: Determine how a good deal space is to be had for installation. Air cooled heat exchangers come in numerous sizes, so it’s crucial to choose one that fits your to be had area.

- Maintenance Needs: While those structures are normally low-maintenance, it’s crucial to pick one that is simple to access and easy in case any renovation is required.

Maintenance Tips for Air Cooled Heat Exchangers

To make sure the lengthy-time period performance of your air cooled warmness exchanger, everyday maintenance is important. Here are some key renovation suggestions:

- Regular Cleaning: Dust and debris can accumulate at the fins and tubes, decreasing the device’s performance. Regularly clean the unit to ensure most preferential airflow.

- Inspect Fans and Motors: Check the enthusiasts and automobiles for any signs and symptoms of wear and tear and tear. Replace or repair any parts that show signs of harm to keep away from breakdowns.

- Monitor Fluid Levels: Ensure that the fluids being cooled are within the required ranges. Any leaks or low fluid ranges can result in reduced performance.

- Check for Corrosion: While air cooled warmth exchangers are designed to be long lasting, it’s still important to inspect for any symptoms of corrosion, mainly if the system is exposed to harsh environmental situations.

Conclusion

If you’re searching out a simple yet effective manner to enhance your industrial cooling device, air cooled warmness exchangers are a super alternative. Their energy efficiency, value-effectiveness, and eco-friendly operation cause them to best for a huge range of applications. Paired with device like Nash liquid ring vacuum pumps, they could create a complete cooling solution that enhances the general performance of your industrial processes.

Investing in air cooled warmth exchangers now not only facilitates you lessen operational costs however also ensures lengthy-term reliability and overall performance, making them a valuable asset for any enterprise.