Laser Cutting Polypropylene Sheets: Tips and Tricks

Introduction

Laser cutting has emerged as a versatile and precise method for cutting various materials, including polypropylene sheets. Polypropylene (PP) is a thermoplastic polymer used extensively in packaging, automotive parts, textiles, and a variety of other applications due to its chemical resistance, durability, and flexibility. Singhal Industries Pvt Ltd, one of the most admired and leading packaging companies in India, is at the forefront of providing high-quality pp sheet manufacturer in Ahmedabad. This article will explore the intricacies of laser cutting polypropylene sheets, offering tips and tricks to achieve the best results. We will also address some frequently asked questions about the process.

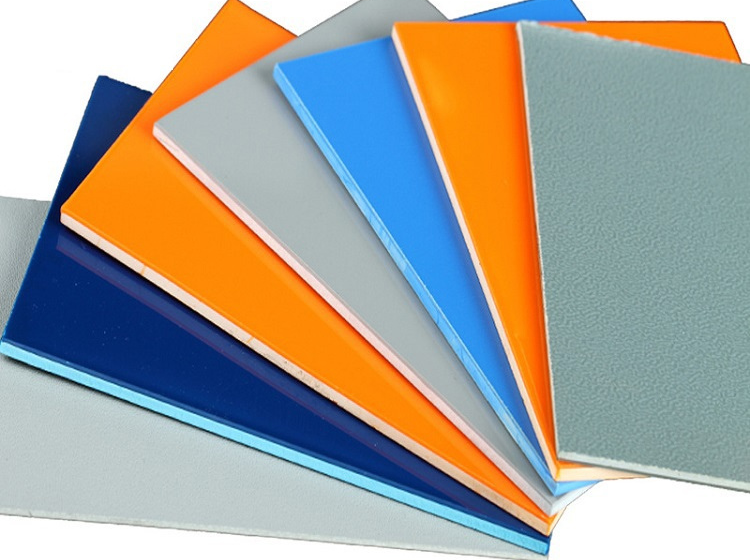

Understanding Polypropylene Sheets

Polypropylene sheets are known for their robustness, lightweight nature, and resistance to chemical corrosion. These attributes make them ideal for various industrial applications. In India, particularly in Gujarat, there are numerous polypropylene sheets manufacturers, including renowned companies like Singhal Industries Pvt Ltd. These manufacturers ensure high standards in the production of PP sheets, catering to diverse needs such as packaging, automotive components, and wall cladding.

Why Laser Cutting?

Laser cutting is preferred for its precision and ability to produce intricate designs without physical contact. The high-energy laser beam melts, burns, or vaporizes the material in a controlled manner, ensuring clean cuts with minimal waste. When it comes to polypropylene sheets, laser cutting offers several advantages:

-

Precision: Achieve detailed and complex shapes with high accuracy.

-

Speed: Faster than traditional cutting methods, increasing efficiency.

-

Quality: Smooth edges with minimal burring.

-

Flexibility: Suitable for both small and large-scale production.

Tips and Tricks for Laser Cutting Polypropylene Sheets

1. Choosing the Right Laser

The type of laser used significantly impacts the quality of the cut. CO2 lasers are commonly used for cutting polypropylene sheets due to their efficiency in handling non-metallic materials. Ensure the laser has the appropriate power settings to cut through the thickness of the PP sheet.

2. Optimizing Power and Speed Settings

Balancing power and speed is crucial. Too much power can cause melting or burning, while too little might not cut through the material. Start with lower power settings and gradually increase until you achieve a clean cut. Similarly, adjust the speed to avoid any discoloration or deformation of the edges.

3. Focus and Beam Alignment

Proper focus and beam alignment are essential for precision. Ensure the laser beam is correctly focused on the material surface. Misalignment can lead to uneven cuts and affect the quality of the final product.

4. Use of Air Assist

Air assist involves blowing a stream of air along the cutting path to remove debris and cool the cutting area. This helps in achieving cleaner cuts and preventing the material from catching fire or melting excessively.

5. Material Preparation

Ensure the polypropylene sheets are clean and free from any contaminants that could interfere with the cutting process. Dust and residues can affect the laser’s efficiency and the quality of the cut.

6. Test Cuts

Before proceeding with the main project, perform test cuts on scrap pieces of polypropylene sheets. This allows you to fine-tune the settings and ensure optimal results without wasting valuable material.

7. Ventilation and Safety

Proper ventilation is crucial when laser cutting polypropylene sheets, as the process can produce fumes. Ensure your workspace is well-ventilated to avoid inhaling any harmful substances. Additionally, always wear appropriate safety gear, such as goggles and gloves, to protect yourself from laser exposure and sharp edges.

Applications of Laser-Cut Polypropylene Sheets

Polypropylene sheets are utilized in various sectors, thanks to their versatility and durability. Here are some common applications:

-

Packaging: Used for creating custom packaging solutions that require precision and durability.

-

Automotive Industry: Employed in manufacturing components like dashboards, door panels, and protective covers.

-

Construction: Ideal for wall cladding and insulation due to their lightweight and sturdy nature.

-

Textiles: Utilized in the production of reusable bags, folders, and other items requiring flexible yet strong materials.

Singhal Industries Pvt Ltd: Leading the Way

Singhal Industries Pvt Ltd, a prominent name among polypropylene sheets manufacturers in Gujarat, continues to set benchmarks in quality and innovation. Their commitment to excellence ensures that their PP sheets meet the highest standards, making them a preferred choice for various applications across India. As a leading pp sheet manufacturer in Ahmedabad, Singhal Industries Pvt Ltd offers an extensive range of polypropylene sheets, catering to the needs of diverse industries.

Their products are widely used for wall cladding, offering an aesthetic and functional solution. The company’s dedication to customer satisfaction and technological advancements keeps them ahead in the competitive market.

Conclusion

Laser cutting polypropylene sheets is an efficient and precise method that offers numerous advantages for various applications. By following the tips and tricks outlined in this article, you can achieve high-quality results while ensuring safety and efficiency. Singhal Industries Pvt Ltd, a leading name among polypropylene sheets manufacturers in Gujarat, continues to provide superior products that cater to diverse industrial needs. Whether you are looking for pp sheet for wall suppliers in India or a reliable pp sheet manufacturer in Ahmedabad, Singhal Industries Pvt Ltd stands out as a trusted and innovative provider in the industry.

Frequently Asked Questions (FAQs)

1. What types of lasers are suitable for cutting polypropylene sheets?

CO2 lasers are the most suitable for cutting polypropylene sheets due to their efficiency in handling non-metallic materials. They provide clean and precise cuts essential for detailed work.

2. Can laser cutting cause any damage to polypropylene sheets?

Improper settings can cause damage such as burning or melting. It is crucial to balance power and speed settings and use air assist to prevent such issues.

3. What are the common applications of laser-cut polypropylene sheets?

Laser-cut polypropylene sheets are commonly used in packaging, automotive parts, construction for wall cladding, and textiles for making reusable bags and folders.

4. How does Singhal Industries Pvt Ltd ensure the quality of their polypropylene sheets?

Singhal Industries Pvt Ltd adheres to stringent quality control measures and uses advanced manufacturing processes to ensure their polypropylene sheets meet the highest standards of durability and performance.

5. Is ventilation important when laser cutting polypropylene sheets?

Yes, proper ventilation is crucial to prevent the inhalation of harmful fumes produced during the laser cutting process. Always ensure your workspace is well-ventilated.

6. Can I cut thick polypropylene sheets with a laser?

Yes, but you need to adjust the laser power and speed settings accordingly. Performing test cuts can help determine the optimal settings for thicker materials.