Exploring the Textures and Finishes of ABS Plastic Sheets

Introduction to ABS Plastic Sheets

Acrylonitrile Butadiene Styrene (ABS) plastic is a widely used thermoplastic known for its versatility and durability. Among the various forms of ABS, sheets are particularly popular in both industrial and creative applications. The 4×8 ABS plastic sheet is a common size that appeals to manufacturers, designers, and hobbyists alike. Available in a variety of textures and finishes, ABS sheets can be tailored to meet specific needs, making them an excellent choice for projects requiring both aesthetics and functionality.

Understanding the Characteristics of ABS Plastic

Before delving into the textures and finishes of ABS plastic sheets, it’s essential to understand the material’s inherent properties. ABS is known for its strength and impact resistance, which makes it suitable for heavy-duty applications. It is also lightweight, easy to fabricate, and has excellent machinability, allowing it to be cut, drilled, or shaped with relative ease. These characteristics contribute to its popularity in various sectors, from automotive components to consumer products.

The Importance of Texture in ABS Sheets

Texture plays a vital role in determining the appearance and feel of ABS plastic sheets. Different textures can affect not only aesthetics but also the sheet’s functionality, such as grip, slip resistance, and visual appeal. The surface texture can be smooth, matte, or glossy, each offering unique advantages depending on the intended application.

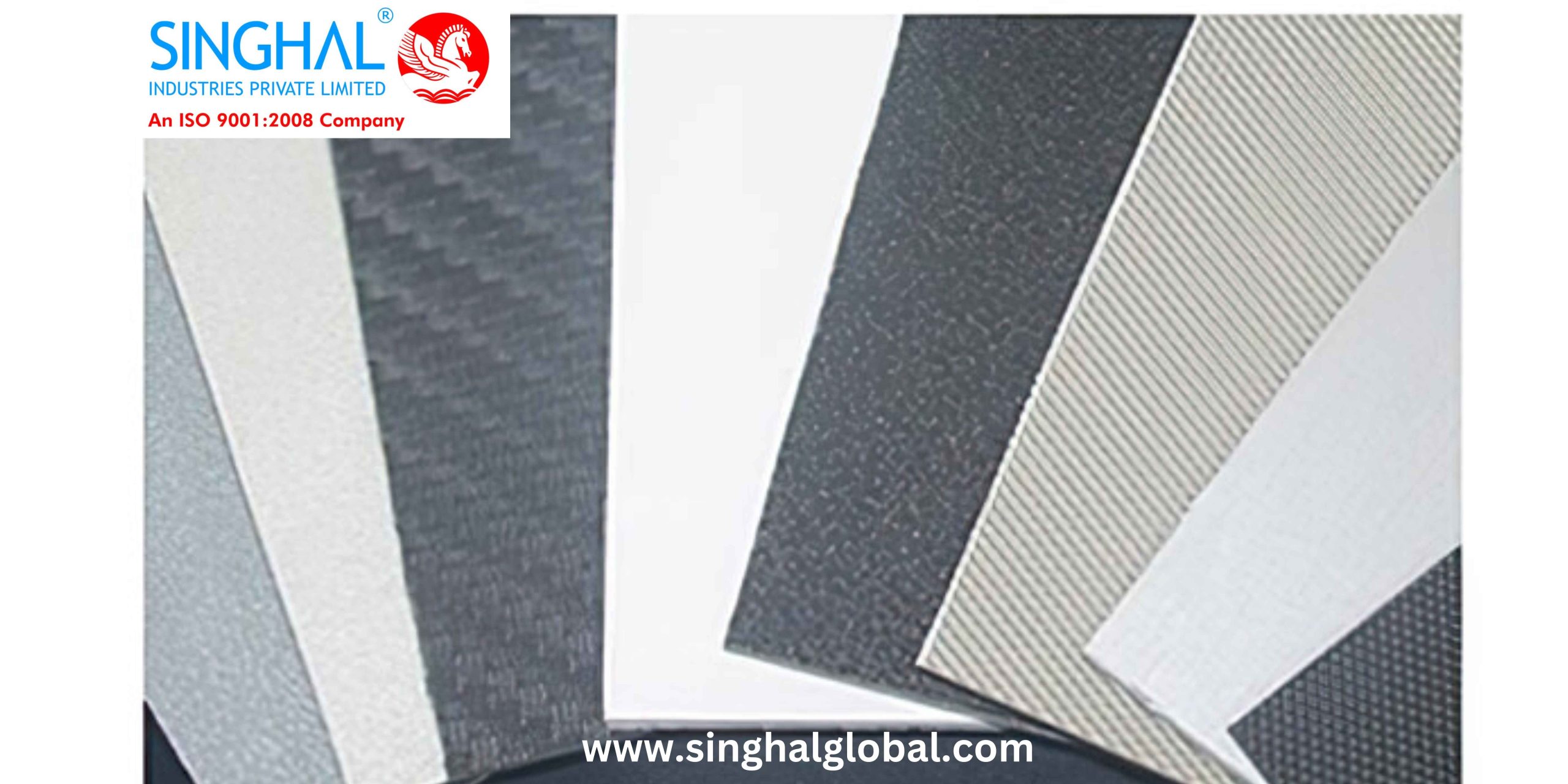

Common Textures Found in ABS Plastic Sheets

Smooth Finish

The smooth finish is one of the most common textures found in ABS sheets. This type of surface is often favored for applications that require a clean, sleek appearance. The smooth finish allows for easy cleaning and maintenance, making it ideal for use in medical equipment, electronic housings, and consumer goods. The 4×8 ABS plastic sheet often features a smooth finish that provides a polished look while maintaining the material’s durability.

Matte Finish

For applications where glare reduction is important, a matte finish is an excellent choice. Matte-textured ABS sheets reduce reflections and provide a softer appearance. This finish is particularly useful in display cases, signage, and furniture design, where a non-reflective surface enhances visual clarity. Additionally, the matte texture can hide fingerprints and smudges better than a glossy finish, making it a practical option for high-traffic areas.

Glossy Finish

A glossy finish on ABS plastic sheets adds a touch of elegance and sophistication. This texture reflects light, creating a vibrant and eye-catching look. Glossy finishes are popular in applications such as custom displays, automotive interiors, and consumer electronics. The shiny surface can enhance colors and designs, making it ideal for promotional materials and product showcases. However, it’s worth noting that glossy finishes may require more frequent cleaning to maintain their appearance.

Textured Finish

Textured ABS sheets can provide a variety of surface patterns, such as embossed or patterned finishes. These sheets are often used in applications where aesthetics and tactile qualities are important, such as in the design of interior panels, decorative elements, or specialty packaging. The unique textures can add depth and character to products while also providing additional grip or friction when needed.

The Benefits of Using 1/4 ABS Sheets

When it comes to thickness, the 1/4 ABS sheet is a favored choice for many applications due to its balanced combination of strength and weight. This thickness provides sufficient durability for structural applications while still being manageable for cutting and shaping. 1/4 plastic sheeting is often used in prototypes, signage, and custom furniture due to its versatility. It offers an excellent balance between rigidity and flexibility, making it suitable for a wide range of uses.

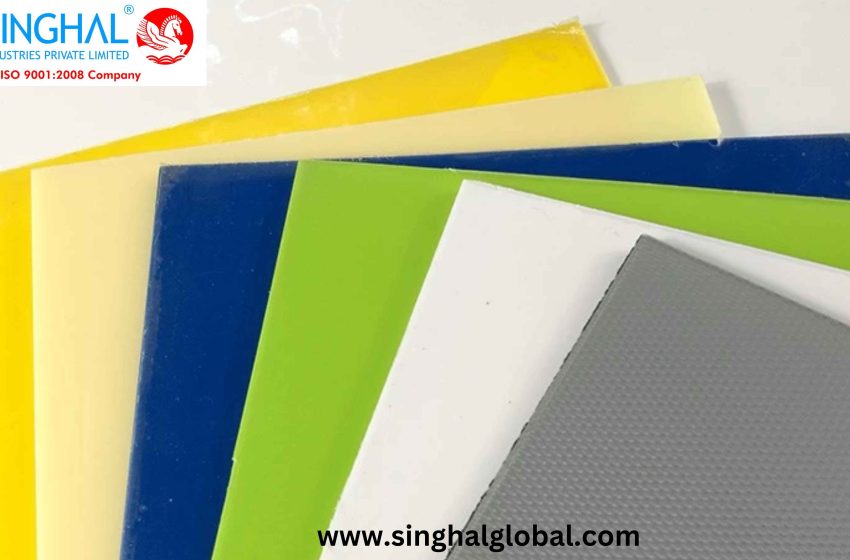

Customization Options for ABS Sheets

One of the standout features of ABS plastic sheets is their ability to be customized. Whether you need a specific texture, color, or thickness, ABS sheets can often be tailored to meet your requirements. Manufacturers can offer various colors, allowing for a broad palette to choose from. Customization extends beyond color and texture; it also includes the option for CNC machining, laser cutting, and printing, enabling precise shapes and designs that cater to specific project needs.

Applications of ABS Plastic Sheets

Automotive Industry

In the automotive sector, ABS plastic sheets are commonly used for interior and exterior components due to their high strength-to-weight ratio. They can be found in dashboard panels, trim pieces, and even in some body parts. The variety of textures available allows manufacturers to create parts that not only perform well but also look appealing.

Signage and Displays

ABS plastic sheets are widely utilized in signage and display applications. Their durability and resistance to environmental factors make them an ideal choice for outdoor signs. The ability to produce sheets with different finishes means businesses can select a look that aligns with their brand identity. Whether opting for a glossy finish to catch the eye or a matte finish to reduce glare, ABS sheets offer flexibility for designers.

Home and Office Furnishings

In the realm of home and office furnishings, ABS sheets are increasingly popular for their aesthetic and functional benefits. Furniture makers often utilize 4×8 ABS plastic sheets to create modern, stylish pieces that are lightweight yet sturdy. The various textures and finishes can elevate the overall design, making it easier to integrate these elements into different decor styles.

Industrial Applications

Beyond aesthetics, the mechanical properties of ABS sheets make them suitable for industrial applications. They can be used for machine housings, protective covers, and even in the manufacturing of custom equipment. The robustness of 1/4 ABS sheets ensures they can withstand harsh environments while providing necessary protection for sensitive components.

Conclusion: The Versatility of ABS Plastic Sheets

In conclusion, the textures and finishes of ABS plastic sheets play a crucial role in determining their applications and effectiveness. From the smooth finish of a 4×8 ABS plastic sheet used in consumer goods to the ruggedness of a textured sheet in industrial settings, the versatility of ABS is unmatched. The 1/4 ABS sheet stands out for its practicality, serving a multitude of purposes across various industries. As manufacturers continue to innovate and expand the possibilities of ABS sheets, the range of textures and finishes will undoubtedly grow, ensuring that this material remains a top choice for countless projects.

In an age where aesthetics and functionality are paramount, exploring the textures and finishes of ABS plastic sheets offers a glimpse into the future of design and manufacturing, making it an essential consideration for anyone working with this remarkable material.

FAQs about ABS Plastic Sheets

1. What is ABS plastic?

ABS (Acrylonitrile Butadiene Styrene) is a type of thermoplastic known for its durability, strength, and impact resistance. It is widely used in various applications, including automotive parts, consumer products, and construction materials.

2. What are the common sizes of ABS plastic sheets?

ABS plastic sheets are available in various sizes, with the 4×8 ABS plastic sheet being one of the most popular. Other sizes may also be available based on specific manufacturer offerings.

3. What thickness options are available for ABS sheets?

ABS sheets come in various thicknesses, including 1/4 inch (1/4 ABS sheet), which is commonly used for many applications due to its balance of strength and weight.