5 Signs Your Automotive Workshop Needs to Switch to Automated Parts Cleaning

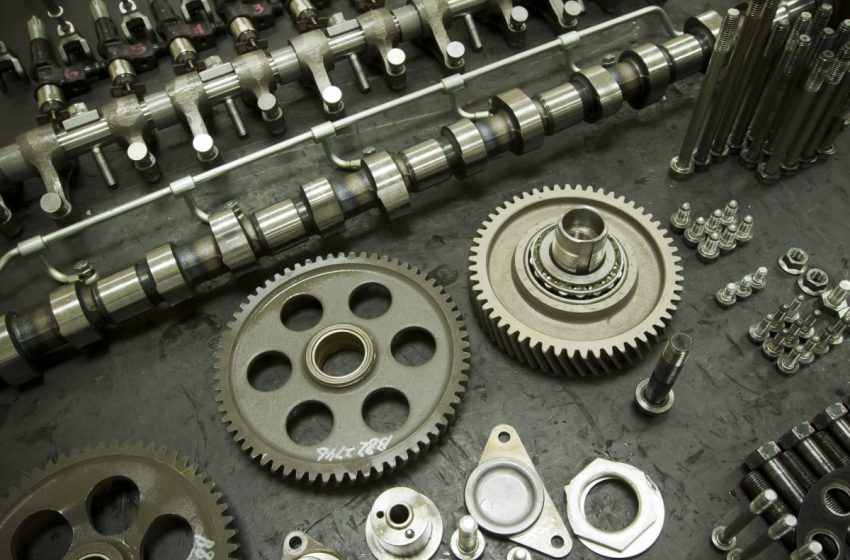

Automotive workshops are evolving, with precision and speed at the forefront of this transformation. At the heart of this evolution is the shift towards automated parts cleaning systems, which promises to refine operations and elevate service quality. Explore this roundup of essential signs indicating a workshop’s readiness for such technological advancements and heralding a new era of operational efficiency service within the automotive industry.

1. Increasing Volume of Work and Limited Capacity

Has your workshop been overwhelmed by an increasing workload? The limitations of manual cleaning become apparent as demand grows. As automotive workshops face escalating workloads, the constraints of manual parts cleaning methods become increasingly evident. This challenge is particularly noticeable on days when a backlog of parts awaiting cleaning leads to notable operational delays.

Such bottlenecks can hinder a workshop’s ability to meet client expectations and deliver timely service. Integrating automated parts cleaning systems offers a robust solution to this issue. These advanced systems are designed to handle larger volumes of work efficiently, enabling workshops to expand their operational capacity significantly. By adopting automation, workshops can ensure consistent service quality, even as demand surges, positioning themselves for sustainable growth and customer satisfaction.

2. Consistency and Quality Concerns

Do you struggle with achieving a consistent clean across all parts? The variability inherent in manual cleaning can lead to quality issues, where the outcome heavily depends on the technician’s expertise. Furthermore, irregular parts with hard-to-reach areas present additional challenges, often requiring specialized attention that manual processes cannot efficiently provide.

Automated systems excel in these situations, utilizing advanced technologies to clean even the most complex parts thoroughly. This capability ensures every part, regardless of shape or complexity, is cleaned to the same high standard, eliminating concerns over missed spots or insufficient cleaning in hard-to-reach areas.

3. Rising Labor Costs and Safety Issues

The automotive industry faces the dual challenges of escalating labor costs and prioritizing worker safety. Manual cleaning is labor-intensive and exposes workers to potential chemical hazards and physical strain. Transitioning to an automated system that uses a water-based parts cleaner can mitigate these concerns. A water based parts washer cleaning solution routine is safer for employees, reducing health risks and possibly lowering insurance costs due to fewer workplace accidents.

4. Environmental and Regulatory Compliance

Meeting environmental standards with traditional cleaning methods is increasingly challenging. The shift toward automated cleaning systems that utilize a water based parts washer cleaning solution aligns with a greener approach. These systems optimize the use of eco-friendly cleaning agents, ensuring compliance with strict environmental regulations and supporting your workshop’s commitment to sustainability.

5. Competitive Pressure and Customer Expectations

In today’s age, customers demand swift, superior service. They also increasingly expect their service providers to use sustainable products that do not harm the environment. Automated parts cleaning accelerates the cleaning process and ensures cleanliness that surpasses manual techniques. This efficiency, combined with an environmentally friendly water based parts cleaner, enhances customer satisfaction and gives your workshop a competitive advantage by aligning with the growing preference for sustainability.

Making the Switch to Automated Parts Cleaning

Upgrading to an automated parts-cleaning system is an innovative move for any automotive workshop. When making this decision, prioritize systems compatible with water based parts cleaner solutions. These solutions are safer for workers and the environment and highly effective against contaminants.

Consider the specific needs of your workshop, such as the volume of parts processed and the available space, to ensure the system you select optimizes your operations without occupying excessive room. Investing in automated cleaning technology promises a significant return through improved efficiency, reduced labor costs, and enhanced compliance with environmental standards, positioning your workshop as a leader in automotive service excellence.

Signs Automotive Workshops Need to Switch to Automated Parts Cleaning…

The transition to automated parts cleaning is a clear choice for workshops facing increased demand, quality control challenges, rising labor costs, environmental compliance issues, and competitive pressures. By adopting systems that utilize water-based parts washer cleaning solutions, workshops can achieve operational efficiency, worker safety, and ecological sustainability, meeting the high expectations of today’s customers and securing a competitive edge in the automotive service industry.